Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Elenco prodotti

Modello: SUF-RC

marchio: SUF

Industria Applicabile: Hotel, Officine di riparazione di macchinari, Uso domestico, Energia e miniere, Compagnia pubblicitaria

Servizio Fuori Da Guerra: Servizio di manutenzione e riparazione del campo, Supporto tecnico video

Dove Fornire Servizi Locali (in Cui I Paesi Ci Sono Punti Vendita All'estero): Egitto, Francia, Arabia Saudita, Spagna, Kenya, Algeria, Kazakistan, Tagikistan

Posizione Dello Showroom (in Cui I Paesi Ci Sono Sale Campioni All'estero): Egitto, Francia, Arabia Saudita, Spagna, Chile, Bangladesh, Nigeria

Vecchio E Nuovo: Nuovo

Tipo Di Macchina: Macchina da forma di piastrelle

Tipo Di Piastrelle: Acciaio

Uso: PAVIMENTO

Produttività: 5 m/min

Luogo D'origine: Cina

Periodo Di Garanzia: 3 anni

Punto Di Forza Core: Facile da usare

Tincezza Rotolante: 0,3-1 mm

Larghezza Di Alimentazione: 1220 mm, 915 mm, 900mm, 1200 mm, 1000 mm

Rapporto Di Test Meccanici: Fornito

Ispezione Di Fabbrica Video: Fornito

Tipo Di Marketing: Nuovo prodotto 2020

Periodo Di Garanzia Dei Componenti Core: Più di 5 anni

Componenti Principali: Recipiente a pressione, Riduttore, Motore, Il motore, Cuscinetto, Plc, Ingranaggio, Pompa

Control System: PLC

Material Of Shaft: 45# Steel

Thickness: 0.3-0.8mm

Voltage: Customized

Certification: ISO

Warranty: 1 Year

Customized: Customized

Condition: New

Control Type: CNC

Automatic Grade: Automatic

Usage: Floor

Tile Type: Colored Steel

Transmission Method: Hydraulic Pressure

Material Of Cutter: Cr12

Material Of Rollers: 45# Steel With Chromed

Material: GI, PPGI For Q195-Q345

Rollers: 10

Pacchetto: NAKED

produttività: 500 SETS

Trasporti: Ocean,Land,Air,by train

Luogo di origine: CHINA

Supportare: 500 SETS

Certificati : ISO 9001 / CE

Codice SA: 84552210

Porta: XIAMEN,TIANJIN,Shanghai

Tipo di pagamento: L/C,T/T,D/P,Paypal,Money Gram,Western UnionL/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CPT,CIPFOB,CFR,CIF,EXW,FCA,CPT,CIP

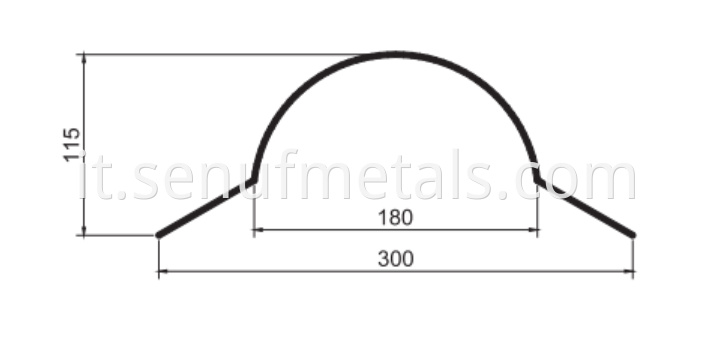

Automatic 115-300 Cap Ridge Cold Roll Forming Machine

This Automatic 115-300 Cap Ridge Cold Roll Forming Machine is used to hold coil, and uncoil it, and feed into roll forming machine. This machine can rotated clockwise and anti clockwith. Also the speed is adjustable. With the help of limit switch box, the decoiler can work with roll forming machine synchronized. It greatly save the labours and improved the working efficiency.

Main features of Automatic 115-300 Cap Ridge Cold Roll Forming Machine

The advantages of Automatic Ridge Cap Roll Forming Machine are as follows:

1. Widely used in many kinds of industrial factory, civilian buildings,

2. Pretty apperance, durable using,

3. Instead using bending machine to make angel tile,

4. Saving human resoureces, lower labor cost

Detailed Images of 115-300 Cap Ridge Roll Forming Machine

Machine Parts

1. 115-300 Cap Ridge Roll Forming Machine feeding guide device

2. Automatic 115-300 Cap Ridge Cold Roll Forming Machine rollers

Roller s manufactured by high quality 45# steel, CNC lathes, Heat Treatment, with black treatment of Harf-Chrome Coating for options,

With feeding material guide, body frame made by 400# H type steel by welding,

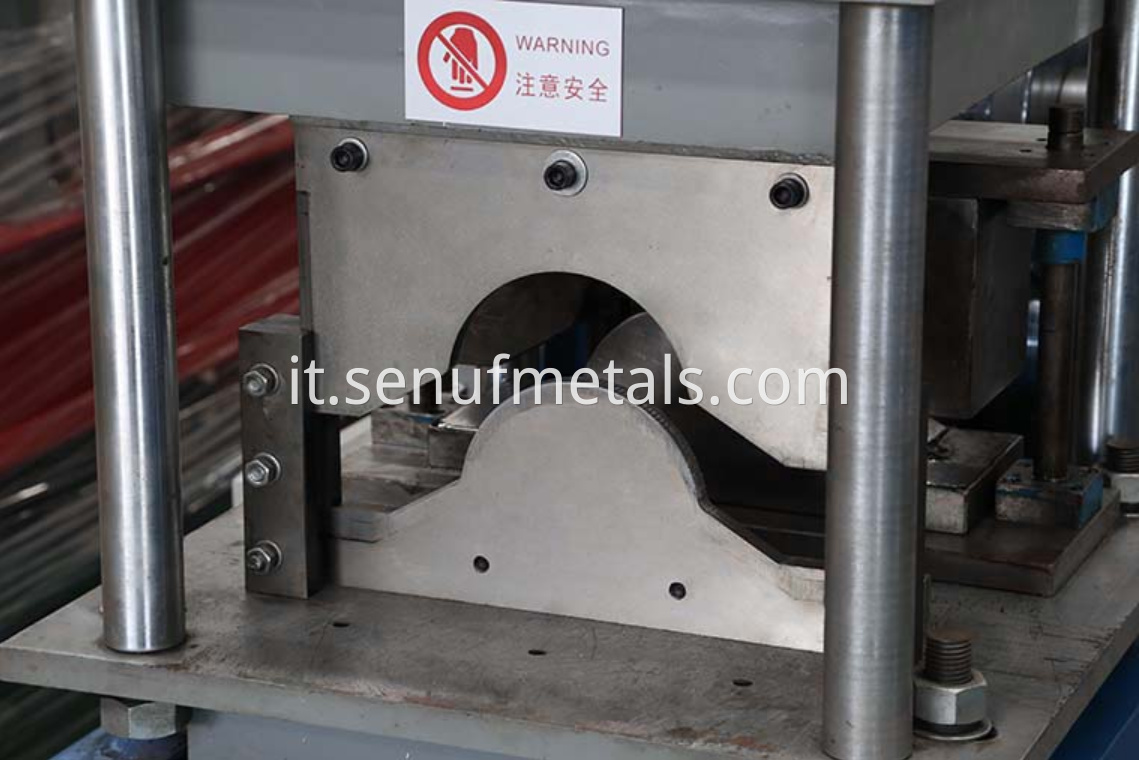

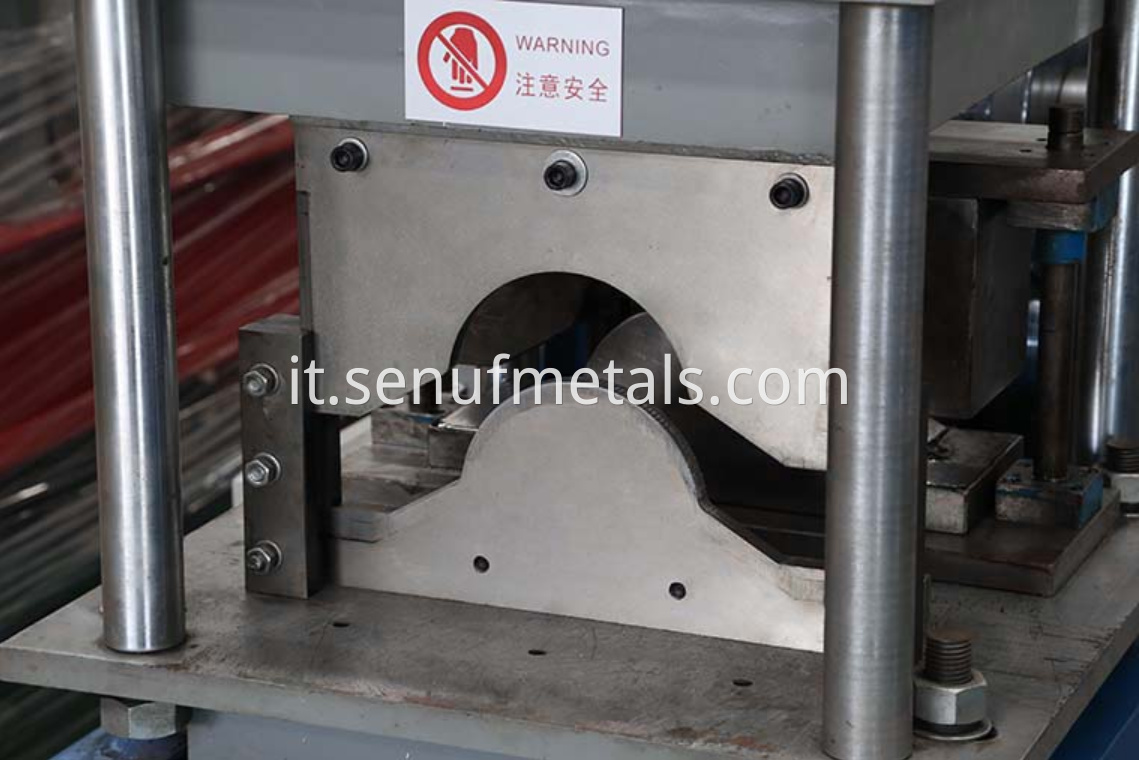

3. Automatic 115-300 Cap Ridge Cold Roll Forming Machine post cutter

Made by high quality mold steel Cr12 with heat treatment,

Cutter frame made by high quality 20mm steel plate by welding,

Hydraulic motor: 2.2kw, hydraulic pressure range: 0-16Mpa

4. Automatic 115-300 Cap Ridge Cold Roll Forming Machine punch mold

5. Automatic 115-300 Cap Ridge Cold Roll Forming Machine PLC control cabinet

6. Automatic 115-300 Cap Ridge Cold Roll Forming Machine decoiler

Manual decoiler: one set

Un-powered, manually control steel coil inner bore shrinkage and stop

Max feeding width: 508mm,

Coil ID range: 470±30mm,

Capacity: Max 3 tons

with 3 tons hydraulic decoiler as optional

7. Automatic 115-300 Cap Ridge Cold Roll Forming Machine exit rack

Un-powered, one set

8. Automatic 115-300 Cap Ridge Cold Roll Forming Machine product sample

Other details of Automatic 115-300 Cap Ridge Cold Roll Forming Machine

Suitable for material with thickness 0.4-0.6mm,

Shafts manufactures by 45#, main shaft diameter 55/75mm, precision machined,

Motor driving, gear chain tranmission, 10 steps to form,

Main motor 4kw, frequency speed control, forming speed approx 12-15m/min

Elenco prodotti : Macchina per laminazione a freddo > Macchina per la formatura di rotoli di fogli di copertura del tetto di colmo

Home > Elenco prodotti > Macchina per laminazione a freddo > Macchina per la formatura di rotoli di fogli di copertura del tetto di colmo > Aluminium roof ridge cap roll former equipment

Invia domanda

Ms. he

Numero Di Telefono:86-311-88035278

Fax:86-311-88035278

Mobile:+8615716889085

E-mail:top1@senufmetals.com

Azienda Indirizzo:499-HEPING WEST ROAD, Shijiazhuang, Hebei

mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.